Overlay & Dropped Trailer Axles

OVERLAY/STEPPED & DROPPED BEAM AXLES

Where a lower deck height is required, the simplest way is to fit overlay/stepped or dropped axles. Car transporter trailers, horse floats, excavator or small mobile machinery trailers are more suited to a lowered deck for both ease of loading/unloading and the increased stability of the trailer due to the lower centre of gravity and reduced wind resistance.

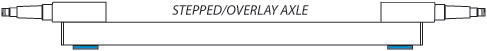

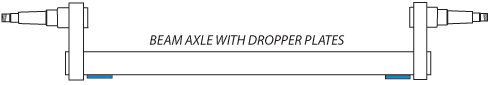

Overlay or stepped axles will reduce the deck height by half the beam axle and stub axle height combined and are useful where a minimal amount of lowering is required. Used in an underslung spring setup reduces the deck height further. It is also a handy way of fitting a stub axle to an axle tube/bar where the internal dimensions of the axle tube do not suit the stub.

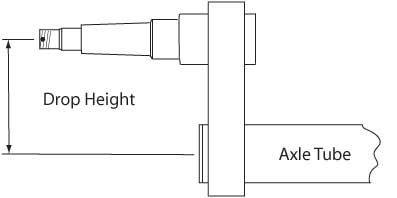

Dropped axles can lower the deck height considerably and common drop heights are between 100-150mm. When used with an underslung spring setup, even more lowering is possible.

If you are ordering a dropped axle from a supplier, the drop height, clearance between the chassis as well as hub to hub face and spring centre measurements will be required.

When using a dropped axle, there need to be a couple of factors taken into consideration as any lowering of the deck height will affect the following -

- The coupling mounting will have to be raised to compensate for the lowered drawbar height.

- Guards will need to be raised and may need to be fabricated longer in their height to give adequate coverage. Raising the guards may interfere with vehicle doors or may protrude over the top of the trailer sides.

- Will there be sufficient ground clearance under the axles/springs especially if the trailer is to be used on building sites or places where the ground is rough and bumpy. Drawbar and chassis clearance will also be reduced and the trailer may drag when going over ramps and kerbs.

- The dropper will take up additional room within the backspace between the hub and chassis. Are your guards wide enough to incorporate dropped axles while maintaining a suitable gap between the trailer and axle? Are your wheel rims big enough to take the dropper height?

Axle Materials

For 1500 to 2000kg axles, the most common material for axle tube is 50 x 50 x 5.0 or 6.0mm SHS (Square Hollow Section). For heavier duty axles, 65 x 65 x 6.0 or heavier is recommended and in some instances, 75 x 50 or larger RHS (Rectangular Hollow Section) sections can be used.

Dropped axles can be manufactured from heavy line/steam pipe but can be a time consuming exercise setting up and welding. Forged solid axles are available in the US.

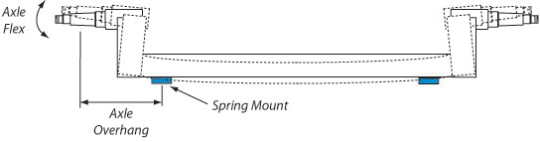

Because of the cantilever action of a dropped axle, axle flex is a bigger problem than a standard straight beam axle.

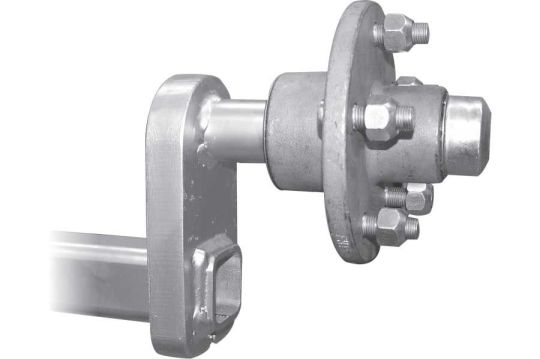

There are plenty of ways to build a dropped axle but by far the simplest is to use pre fabricated dropper plates.

Most trailer part suppliers will have dropper plates in stock with standard drop centre heights of 65, 100 & 150mm.

Dropper plates are normally manufactured from 25mm plate, but if you have access to a gas cutter or plasma cutter you can make your own from 5 or 6mm plate/flat bar and laminate them together for super strong dropper plates.

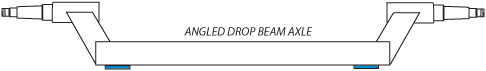

If you are planning on using SHS (Square Hollow Section), the ideal dropper tube arrangement is the angled drop beam setup where the dropper tube has a greater amount of welding along both the vertical and horizontal planes, giving greater strength than the end butt setup as shown above. The disadvantage of this style is the overhang is slightly increased.

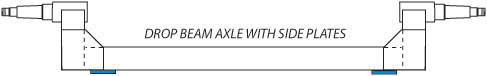

For a good heavy duty dropped axle with ease of manufacture, the drop beam axle with side plates is recommended. The gusset side plates give good strength to the dropper tubes and stiffen the axle considerably. Care needs to taken to ensure there is sufficient clearance between the chassis and side plates.

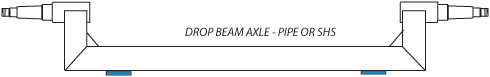

Using 45 degree joints between the drop tubes and the axle tube, as well as small central gussets will give a good strong axle that is relatively easy to manufacture. The advantage of this design is that both SHS and pipe can be used. If using pipe, heavy duty spring saddles should be welded on to prevent the axle rotating on the springs.

Axles for offroad or extreme use trailers should always be professionally manufactured and ideally be of solid construction.

For information on building Overlay/Stepped Axles click here.

For information on building Dropped axles using dropper plates click here