RV Axle Flipping - Part 2

Continued on from Axle Flipping -

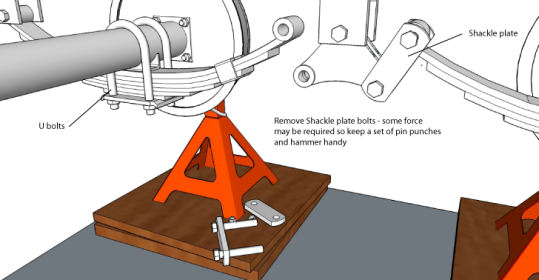

To do this, loosen the nut slightly and give the nut a tap directly and squarely with a brass/copper face hammer. Loosen the nut another turn or two and give it another tap. All things going well, movement should be seen and continuing this procedure will remove the bolt quickly.

If the bolt is being stubborn or corrosion has set in, apply some penetrating oil (CRC/WD40 or similar) and leave for 20 minutes or so before again attempting removal.

Patience and perseverance will always win in the end, just be sure not to get frustrated and end up damaging the end of the bolt to the point where some serious cutting and grinding will need to be done to remove the bolts!

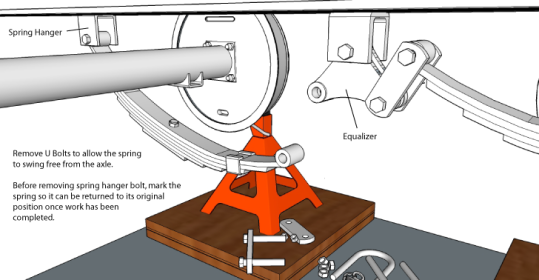

Once the shackle plates are removed, loosen and remove the axle U bolts and let the spring hang free.

Mark and label each spring before removal, so that it can be fitted back into its original position if you are replacing the spring bushings.

Using a trolley jack, raise the axle off the jack stands and lower it gently to the ground.

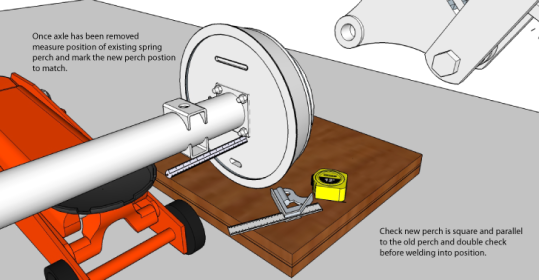

With the axle free from the trailer, measure the position of the existing spring perch and position the new spring perch over the top of the axle. Square the new perch so that it is perfectly parallel to the original.

Clamp the new perch in position and double check all measurements match the existing perch. When satisfied, weld securely onto the axle.

When welding the new spring perch, make sure the earth clamp is mounted on the axle tube and not around or on the hub or backing plate. Any welding current passing through the wheel bearings will damage them and cause premature failure.

Do not make any attempt to remove the old spring perch from the axle, doing so could compromise and weaken the axle.

If you have been supplied with “no weld” spring perches, follow the manufacturer’s instructions for the correct fitting procedure.

Check around the spring and equalizer hangers for any wear, damage, cracks or faulty welding. Remedy any faults before continuing.

Now is a good time to fit the new spring bushings, equalizer and shackle plates and bolts if required.

If possible source and fit new bolts with zerk fittings (grease nipples) to allow lubrication of the moving parts. This will give your trailer suspension a quieter, smoother ride and a longer life if greased regularly.

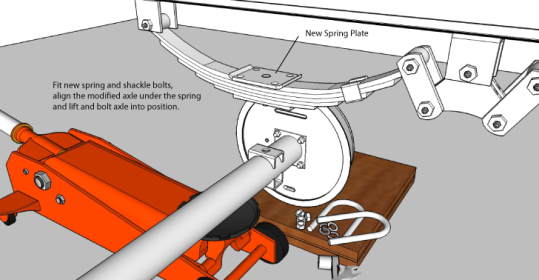

At the bare minimum, new U bolts and spring plates should be used. Do not reuse the old ones if you can help it.

Loosely tighten the U bolts on both sides of the axle until you are sure the spring holes in both the spring plate and new spring perch line up and are centralized.

Tighten up the U bolts evenly going around the nuts equally to prevent any excess tension placed on any one side, then torque the nuts up to the manufacturers recommended setting.

Double check all spring hanger, shackle and equalizer bolts are torqued up to the correct setting and everything is looking as it should.